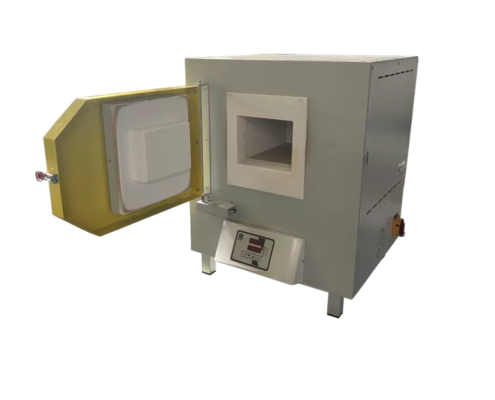

LABORATORY KILN LKN series

It is a series of electric kilns used in the thermal processes

of metallurgical, chemical, dental and ceramic laboratories.

They have been designed to obtain the best compromise between the heating speed

and the operating life of both the resistances and the thermal insulation.

The combination of preformed ceramic fi ber panels, low density refractory bricks, and high quality resistances, allow to

these kilns a rise in temperature and a cooling that allow them to work in combination with intermittent kilns.

Technical specifications

The structure in fi re-painted steel with epoxy paints, and support feet with rubber base, make the kilns of the

LKN series compact, light and that can be placed on any laboratory table or bench.

The heating part is made up of:

- Resistors made with spring-shaped Khantal-type wire and mounted on ceramic glow plugs (LKN-76 and LKN-86 models)

- Resistors in “silicon carbide ” (LKN-77 and LKN-8 models)

- Resistors in “molybdenum disilicide” (LKN-78 / LKN-79 / LKN-88 / LKN-89 models)

In the back there is a chimney for the exit of any gases that could form during the cooking phases,

and to help in the cooling phase (natural type).